Filtration is an essential part of many industrial applications. From water treatment plants to food and beverage production, from pharmaceuticals to chemicals, filtration plays a crucial role in maintaining the quality and purity of the end product. Traditional filtration systems involve the use of various filter media such as paper, cloth, sand, or activated carbon, which have certain limitations in terms of filtration efficiency, durability, and cost-effectiveness. However, with recent advancements in materials science and engineering, a new type of filtration technology has emerged that offers superior performance and versatility- Five Layer Sintered Mesh.

What is Five Layer Sintered Mesh?

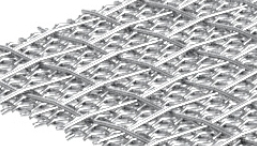

Five Layer Sintered Mesh is a type of wire mesh filter that consists of five layers of stainless steel wire mesh, each with a different pore size and wire diameter, bonded together using a high-temperature sintering process. This unique construction provides the filter with several key properties that make it superior to other filter media:

1. High Filtration Efficiency

Five Layer Sintered Mesh has a high filtration efficiency due to its multi-layered structure. The smaller pore size of the inner layers captures fine particles while the larger pore size of the outer layers provides support and prevents clogging. The result is a filter that can remove particles as small as 1 micron (0.001mm), making it suitable for use in critical applications such as gas and liquid purification.

2. High Strength and Durability

Five Layer Sintered Mesh is made of high-quality stainless steel wire, which is resistant to corrosion, oxidation, and abrasion. The sintering process bonds the wire mesh layers together to form a rigid and robust filter that can withstand high pressure, temperature, and mechanical stress. This makes it ideal for use in harsh environments where traditional filters would fail.

3. Easy to Clean and Reuse

Five Layer Sintered Mesh can be cleaned and reused multiple times, reducing waste and saving costs. The smooth surface of the filter allows for easy cleaning using a variety of methods such as backwashing, ultrasonic cleaning, or chemical cleaning. The filter can also be regenerated by heating it to a high temperature to burn off any accumulated contaminants.

Where is Five Layer Sintered Mesh Used?

Five Layer Sintered Mesh is used in a wide range of industrial applications, including:

1. General Filtration

Five Layer Sintered Mesh is used as a general-purpose filter in various industries, such as automotive, aerospace, and marine. It is used to remove particulate matter from fuels, lubricants, hydraulic fluids, and cooling water.

2. Filtration & Separation Supports

Five Layer Sintered Mesh is used as a support element in filtration and separation systems. It provides a stable and uniform surface for filter media such as activated carbon, zeolites, or ion exchange resins. This results in improved filtration efficiency and longer service life of the filter media.

3. Industrial Mesh Supports & Inlays

Five Layer Sintered Mesh is used as a reinforcement element in industrial mesh screens and wire cloth. It provides additional strength and stability to the mesh, preventing it from sagging or deforming under stress. It is also used as an inlay material in perforated metal and expanded metal sheets to improve their structural integrity and provide a uniform distribution of openings.

Conclusion

Five Layer Sintered Mesh is a revolutionary type of wire mesh filter that offers superior filtration efficiency, durability, and versatility. Its unique construction and properties make it ideal for use in a wide range of industrial applications, including general filtration, filtration & separation supports, and industrial mesh supports & inlays. As the demand for high-performance filtration systems continues to grow, Five Layer Sintered Mesh is poised to become the go-to solution for many industries.