Xinxiang Zhengyuan Purification Science and Technology Co., Ltd. is a trusted high-tech enterprise that specializes in the research and production of high-end metal filter materials, filtration products/systems, pressure vessels, reaction stills, and towers. One of their primary offerings is their sintered wire mesh, which has been bonded by diffusion annealing. This innovative filter medium is preferred by several industries due to its high filtration efficiency, durability, and versatility.

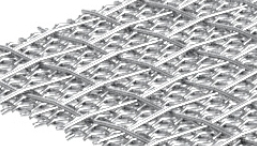

Sintered wire mesh is made of multiple layers of stainless steel wire mesh, which is sintered together using a vacuum furnace. This process ensures that the layers of wire mesh bond together, creating a strong and rigid material. The filtration capability of sintered wire mesh is enhanced because of the tiny pores created in the sintering process, which allow for finer particle filtration.

One of the benefits of sintered wire mesh is its durability. The material is resistant to heat, corrosion, and wear and tear, making it ideal for use in high-temperature and harsh chemical environments. The material is also stable under high pressures, which means that it can be used for critical applications without the risk of deformation or rupture.

Another benefit of sintered wire mesh is its versatility. There are several different types of sintered wire mesh, each with unique properties that make them suitable for a variety of filtration applications. For example, nickel sintered mesh is ideal for use in chemical processing, while monel sintered mesh is used in marine applications due to its high resistance to saltwater corrosion.

Sintered mesh filter elements are another popular application of sintered wire mesh. These elements are used in liquid and gas filtration systems and are designed to remove contaminants from fluids or gases by passing them through a porous medium. The size and shape of the pores in the mesh can be customized to meet specific filtration requirements, making sintered mesh filter elements an extremely effective filtration option.

Sintered square woven mesh is another type of sintered wire mesh that is preferred by several industries. This mesh is made by weaving several layers of stainless steel wire mesh together and then sintering them together to create a strong and durable material. This type of mesh is ideal for use in high-temperature, abrasive, and corrosive environments.

In summary, sintered wire mesh is a versatile and durable filtration material that is ideal for use in several industries. Its high filtration efficiency, durability, and resistance to heat, corrosion, and wear and tear make it a popular choice for critical applications. Xinxiang Zhengyuan Purification Science and Technology Co., Ltd. is a trusted provider of sintered wire mesh, offering a wide range of options to meet the unique filtration needs of their clients.